DIN985 Nylon Self-Locking Nut Anti-Slip hex coupling nuts

Description

Self locking nuts generally rely on friction, and their principle is to press the embossed teeth into the preset holes of the sheet metal. Generally, the aperture of the preset holes is slightly smaller than that of the riveted nuts. Connect the nut to the locking mechanism. When tightening the nut, the locking mechanism locks the ruler body and the ruler frame cannot move freely, achieving the purpose of locking; When loosening the nut, the locking mechanism disengages the ruler body and the ruler frame moves along the ruler body.

Self locking nuts are a new type of high vibration resistant and anti loosening fastening component that can be applied to various mechanical and electrical products at temperatures ranging from -50 to 100 ℃. The demand for nylon self-locking nuts in aerospace, aviation, tanks, mining machinery, automobile transportation machinery, agricultural machinery, textile machinery, electrical products, and various types of machinery has increased sharply. This is because its anti vibration and anti loosening performance is much higher than other anti loosening devices, and its vibration life is several times or even dozens of times higher.

The double ear sealed floating self-locking nut specified in GJB125.1~125.6-86 consists of four parts: sealing cover, self-locking nut, pressure ring, and sealing ring. It has a compact structure and reliable sealing, suitable for products with working pressure not exceeding 2 atm, working medium of gasoline, kerosene, water or air, and operating temperature ranging from -50 to 100 ℃. But it has certain difficulties in manufacturing processes and airtightness tests.

Dongguan Yuhuang Electronic Technology Co., Ltd. was established in 1998, mainly dedicated to the research, development, customization, and production of non-standard fasteners. The company has two production bases, Dongguan Yuhuang with an area of 8000 square meters and Lechang Science and Technology Park with a factory area of 12000 square meters. We have passed ISO9001, ISO14001, and IATF16949 certifications, and all products comply with REACH and ROHS standards.

Company Introduction

customer

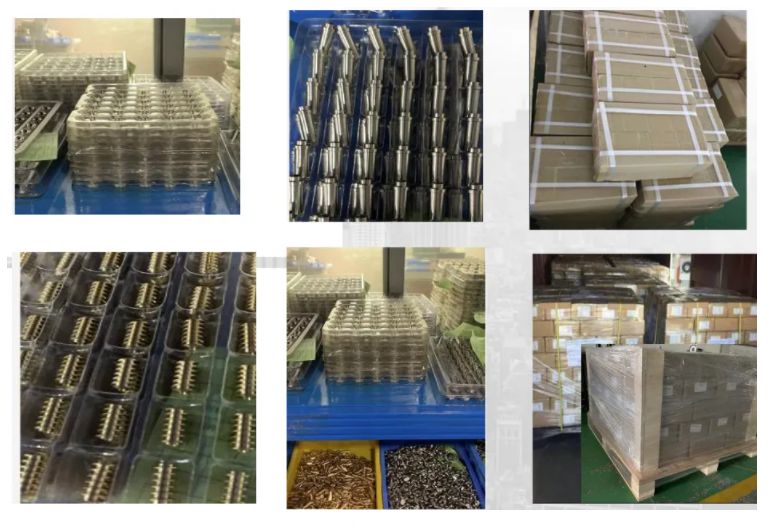

Packaging & delivery

Quality inspection

Why Choose Us

Customer

Company Introduction

Dongguan Yuhuang Electronic Technology Co., Ltd. is mainly committed to the research and development and customization of non-standard hardware components, as well as the production of various precision fasteners such as GB, ANSI, DIN, JIS, ISO, etc. It is a large and medium-sized enterprise that integrates production, research and development, sales, and service.

The company currently has over 100 employees, including 25 with more than 10 years of service experience, including senior engineers, core technical personnel, sales representatives, etc. The company has established a comprehensive ERP management system and has been awarded the title of "High tech Enterprise". It has passed ISO9001, ISO14001, and IATF16949 certifications, and all products comply with REACH and ROSH standards.

Our products are exported to more than 40 countries worldwide and are widely used in various industries such as security, consumer electronics, new energy, artificial intelligence, household appliances, automotive parts, sports equipment, healthcare, etc.

Since its establishment, the company has adhered to the quality and service policy of "quality first, customer satisfaction, continuous improvement, and excellence", and has received unanimous praise from customers and the industry. We are committed to serving our customers with sincerity, providing pre-sales, during sales, and after-sales services, providing technical support, product services, and supporting products for fasteners. We strive to provide more satisfactory solutions and choices to create greater value for our customers. Your satisfaction is the driving force for our development!

Certifications

Quality inspection

Packaging & delivery

Certifications