Fastener Hex Bolt Full Thread Hexagon Head Screw Bolt

Description

Hexagonal screws have hexagonal edges on the head and no indentations on the head. In order to increase the pressure bearing area of the head, hexagonal flange bolts can also be made, and this variant is also widely used. In order to control the friction coefficient of the bolt head or improve the anti loosening performance, hexagonal combination bolts can also be made.

In order to ensure tightening quality and automation requirements during production, assembly is carried out through fixed torque wrenches and high-precision tightening guns. Therefore, corresponding tightening sleeves need to be matched, and the sleeves of hexagonal bolts are concave hexagonal. Hexagonal bolts will be equipped with hexagonal wrenches, such as adjustable wrenches, ring wrenches, open end wrenches, etc.

Hexagon bolts/screws: good self-locking performance; Large pre tightening contact area and high pre tightening force; A wider range of full thread lengths; There can be reamed holes that can fix the position of the parts and withstand shear caused by lateral forces.

In what situations will hexagonal bolts be used?

If the axial force required at the tightening point is large, that is, the tightening torque is large, and the external tightening space is sufficient, the hexagon bolt shall be used for tightening. If there is space limitation in the tightening position, or there is a need to make a countersunk head aesthetically pleasing, and the axial force required for the tightening point is not large, that is, the tightening torque is not large, then the inner hexagon can be made. Taking a car as an example, at the connection position between the subframe and the body, several bolts pass through the subframe through the bottom and are tightened to the body. As the bottom is an invisible area with no aesthetic requirements, there is no interference in tightening, and the required axial force and torque for tightening are large (bolts are tightened after yielding). For this connection position, hexagonal bolts are suitable for tightening.

We have cooperated with many automotive customers, such as Funeng, Guanyu, etc., with a wide range of automotive products and a complete management system for product quality. We can also provide customers with fastener matching products for one-stop procurement. For more information, please feel free to contact us via email!

Company Introduction

customer

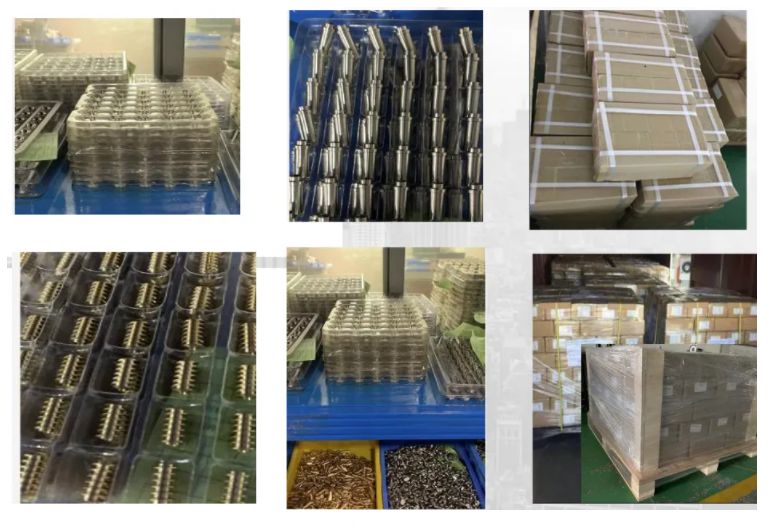

Packaging & delivery

Quality inspection

Why Choose Us

Customer

Company Introduction

Dongguan Yuhuang Electronic Technology Co., Ltd. is mainly committed to the research and development and customization of non-standard hardware components, as well as the production of various precision fasteners such as GB, ANSI, DIN, JIS, ISO, etc. It is a large and medium-sized enterprise that integrates production, research and development, sales, and service.

The company currently has over 100 employees, including 25 with more than 10 years of service experience, including senior engineers, core technical personnel, sales representatives, etc. The company has established a comprehensive ERP management system and has been awarded the title of "High tech Enterprise". It has passed ISO9001, ISO14001, and IATF16949 certifications, and all products comply with REACH and ROSH standards.

Our products are exported to more than 40 countries worldwide and are widely used in various industries such as security, consumer electronics, new energy, artificial intelligence, household appliances, automotive parts, sports equipment, healthcare, etc.

Since its establishment, the company has adhered to the quality and service policy of "quality first, customer satisfaction, continuous improvement, and excellence", and has received unanimous praise from customers and the industry. We are committed to serving our customers with sincerity, providing pre-sales, during sales, and after-sales services, providing technical support, product services, and supporting products for fasteners. We strive to provide more satisfactory solutions and choices to create greater value for our customers. Your satisfaction is the driving force for our development!

Certifications

Quality inspection

Packaging & delivery

Certifications