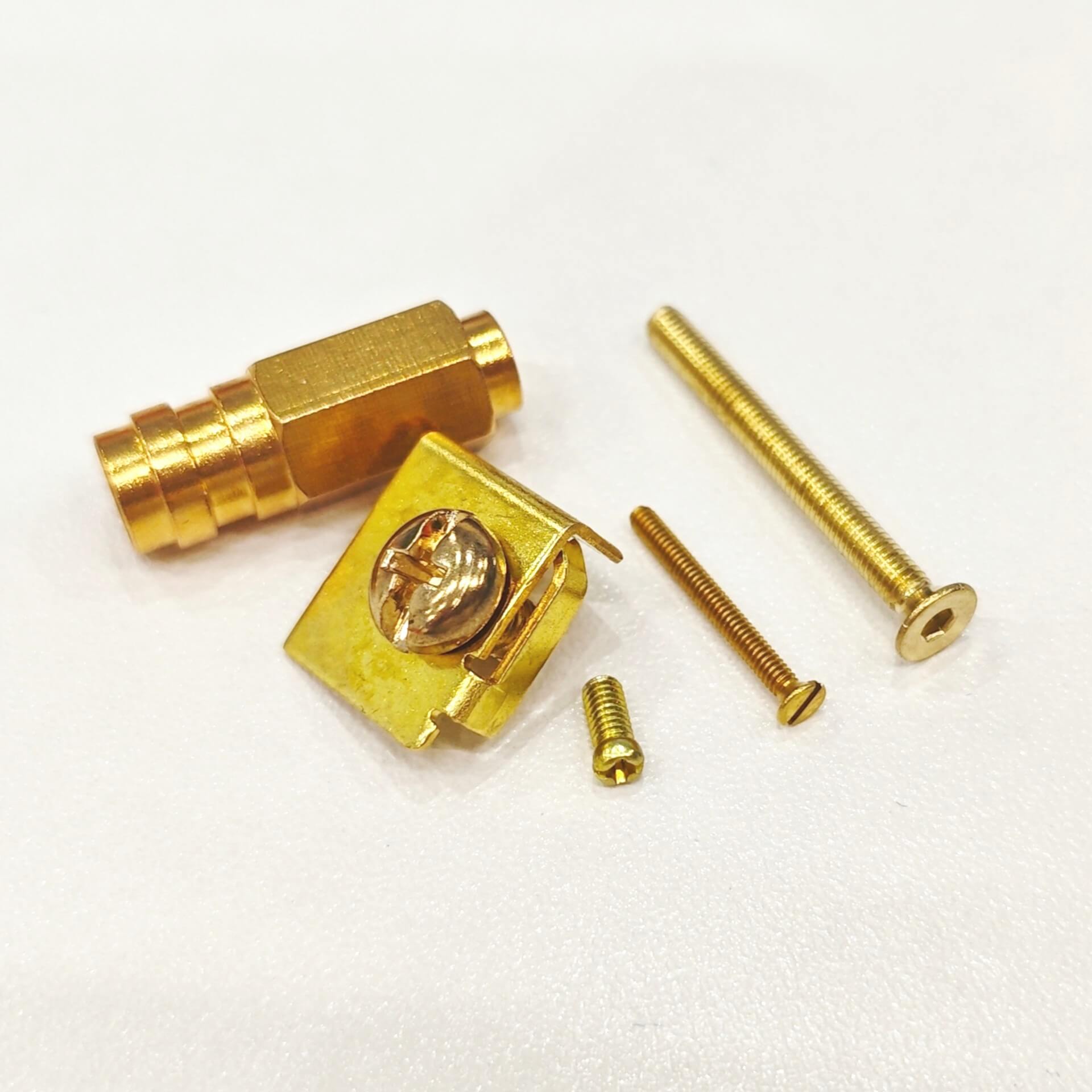

Brass screws are valued for their excellent corrosion resistance, non-magnetic properties, and attractive appearance. Made from high-quality brass alloy, these screws are ideal for applications requiring electrical conductivity, rust resistance, and a decorative finish. They are widely used in electronics, marine environments, automotive systems, medical devices, and precision instruments.

Applications of Brass Screws

1.Electronics and Electrical Equipment

Applications: Circuit boards, connectors, electrical enclosures, and communication devices.

Function: Provide secure fastening with good conductivity and anti-interference characteristics.

2.Marine and Outdoor Equipment

Applications: Ship instruments, sensors, coastal monitoring devices, and outdoor electrical systems.

Function: Resist corrosion in humid or saltwater environments.

3.Medical and Laboratory Instruments

Applications: Surgical tools, diagnostic devices, and laboratory equipment.

Function: Ensure cleanliness, corrosion resistance, and compatibility with sterilization processes.

4.Automotive and Aerospace

Applications: Electrical systems, sensors, connectors, and interior decorative parts.

Function: Deliver non-magnetic and vibration-resistant performance in sensitive environments.

5.Decorative and Precision Products

Applications: Optical instruments, luxury packaging, musical instruments, and high-end consumer products.

Function: Enhance aesthetic appeal while providing reliable fastening.

How To Order Custom Brass Screws

At Yuhuang, ordering custom brass screws is a streamlined and efficient process:

1.Specification Definition:Determine your requirements, including material grade, screw type (e.g. cross slot, self-tapping, flat slot, or Torx), dimensions (diameter, length, thread type), head style, and any special surface treatments.

2.Consultation Initiation:Contact our team to discuss your needs or arrange a technical consultation. Our experts will provide tailored advice to optimize the brass screw design for your application.

3.Order Confirmation:Finalize order details such as quantity, delivery schedule, and pricing. Production begins promptly upon your approval, with strict adherence to your specifications.

4.Timely Fulfillment:Your order receives priority handling to ensure on-time delivery, supported by our efficient manufacturing and logistics processes to meet your project deadlines.

FAQ

Q: What are the main advantages of brass screws?

A: They offer excellent corrosion resistance, non-magnetic properties, good electrical conductivity, and an aesthetically pleasing appearance.

Q: In which industries are brass screws commonly used?

A: They are widely used in electronics, marine, medical, automotive, aerospace, and decorative industries.

Q: Can brass screws be used in high-temperature environments?

A: Brass has a relatively low melting point compared to steel, so it is not suitable for sustained high-temperature applications. Alternative materials should be considered for such conditions.

Q: Do you offer custom-designed brass screws?

A: Yes, we support customization in dimensions, material composition, head style, drive type, and surface treatment based on your needs.

Should you require brass screws with specific features or applications, our technical team is ready to assist you with professional solutions and services.

Machine Screw

Machine Screw Self tapping Screw

Self tapping Screw Sealing screw

Sealing screw thumb screw

thumb screw